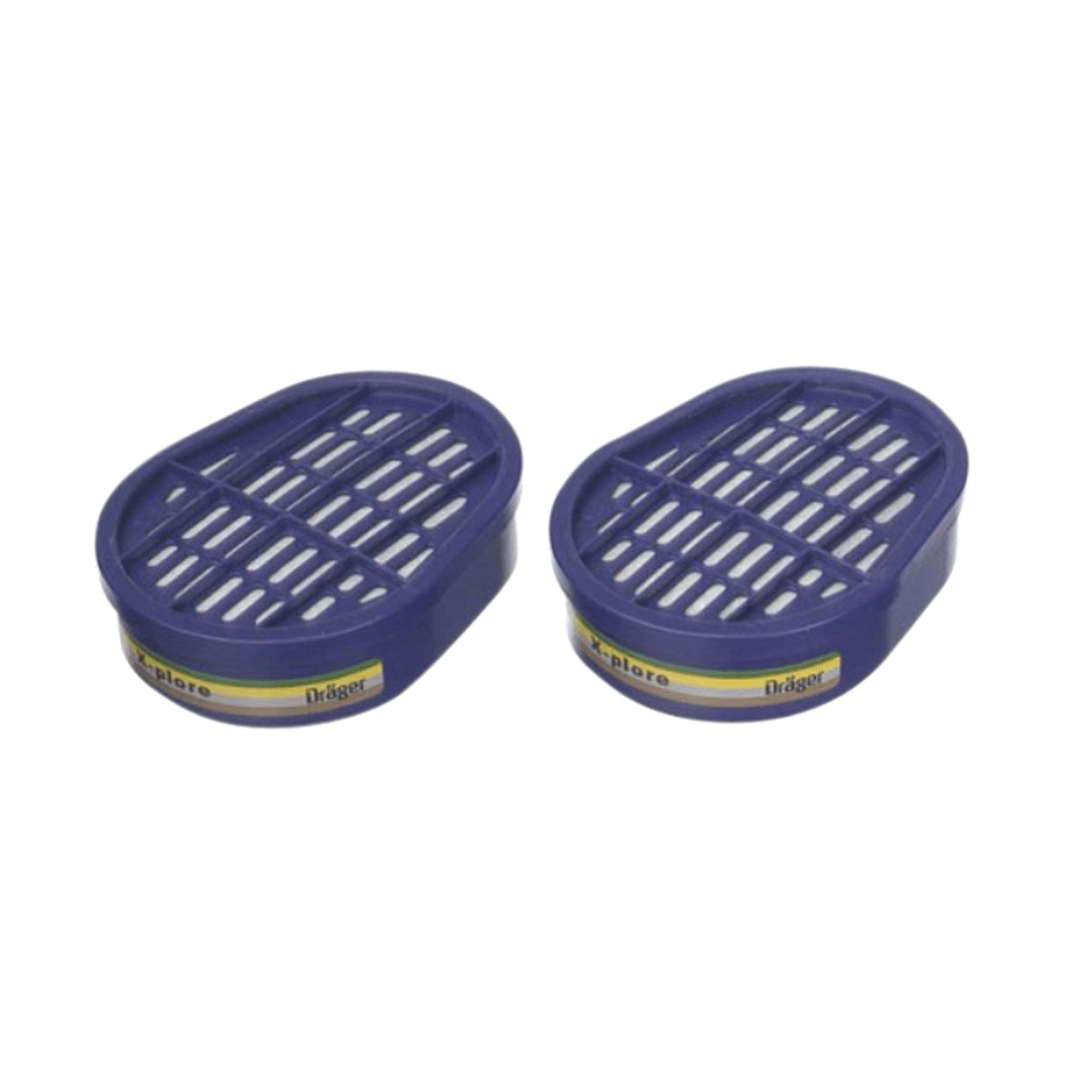

Respiratory protective devices are a special type of PPE, manufactured to protect workers from inhaling hazardous substances in the air of the workplace. These masks are used as a last resort in the hierarchy of control measures, where an adequate control of exposure is not possible with other means. The filters are one of their components and they are inserted on the face masks and half-face masks to capture solid and/or aeriform contaminants. They are characterised by colours or coloured stripes to protect against different types of contaminants while those protecting against dust are white.

EN 14387 refers to the gas filters (suitable for protection against gases and vapours) and combined filters for use as replaceable components in unassisted respiratory protective devices. There are three protection classes for each type of filter which differentiate their increasing absorbance capacity and therefore their duration (set at a standard of 100%).

Marked with numbers 1, 2, 3 determining the class, the filter can be identified by a specific colour and its association with a letter or number, for example:

A) Brown. Protection against organic vapours with a boiling point above 65°C.

B) Grey. Protection against organic gases and vapours (chloride, hydrocyanic acid, hydrogen sulphide).

E) Yellow. Protection against acid gases (sulphur dioxide, hydrochloric acid).

K) Green. Protection against ammonia and its organic derivatives.

All three classes, regardless of the aeriform concentration present, have the same capacity of capturing contaminants. What changes is the time during which this property is assured.

Considering that higher filter classes also have increased respiratory resistance of the air passage device, at times it is preferable to use filters with a lower capacity but that provide greater breathing comfort though guaranteeing the same protection for a shorter time.

EN 14387

Products for this standard