The EN 388 standard specifies requirements, test methods, marking and information to be supplied for gloves which protect against the mechanical risks of abrasion, blade cut, tear, puncture and, if applicable, impact. Referring to work gear such as protective gloves, against mechanical risks such as: abrasion, blade cut, tear and puncture.

The standard has a pictogram with numbers explaining the protective level of the glove and how the tests are carried out to declare their level.

Abrasion: This level is determined based on the number of cycles the glove can undergo before being ruined or punctured.

Cut resistance: By placing the device in contact with a rotary blade, the level is established based on how many rotations the glove can undergo before being cut.

Tear: The device is already cut before starting the test. In fact, this resistance level is measured by verifying the protective effectiveness of the glove to tearing when already broken.

Puncture: This level is determined after pressing of a point to puncture the tested item.

The performance level, normally indicated with a number from 0 to 4 (5 for cut protection), reflects the protective level depending on its behaviour when undergoing a certain test. This ranking therefore makes it possible to classify the test results and levels of protection against a risk. Level 0 indicates that the glove was not tested or did not meet the minimum requirements. Performance level X indicates that the test method is not suitable for the glove sample tested. Lastly the higher it is the higher will the performance level be, and therefore protection.

EN 388

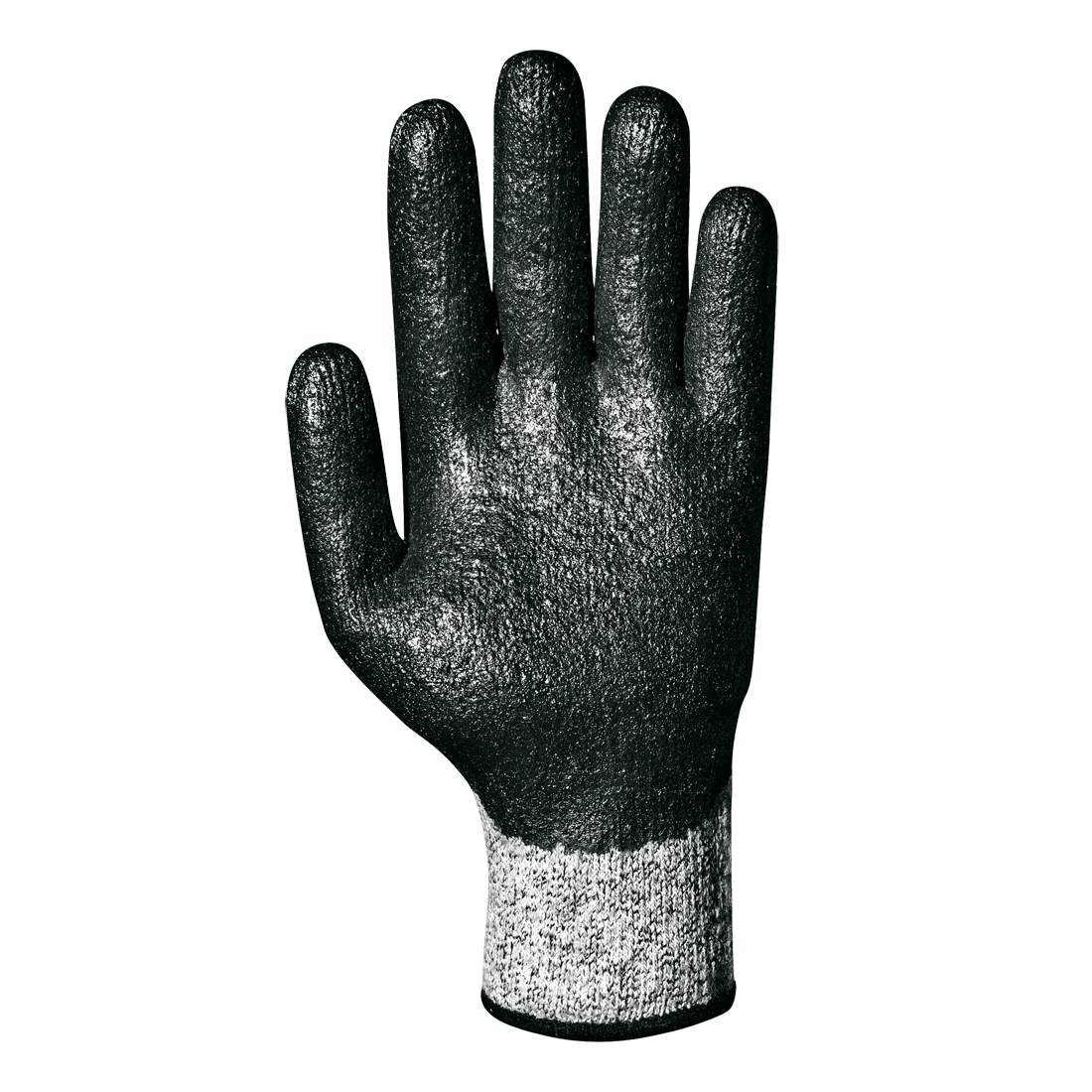

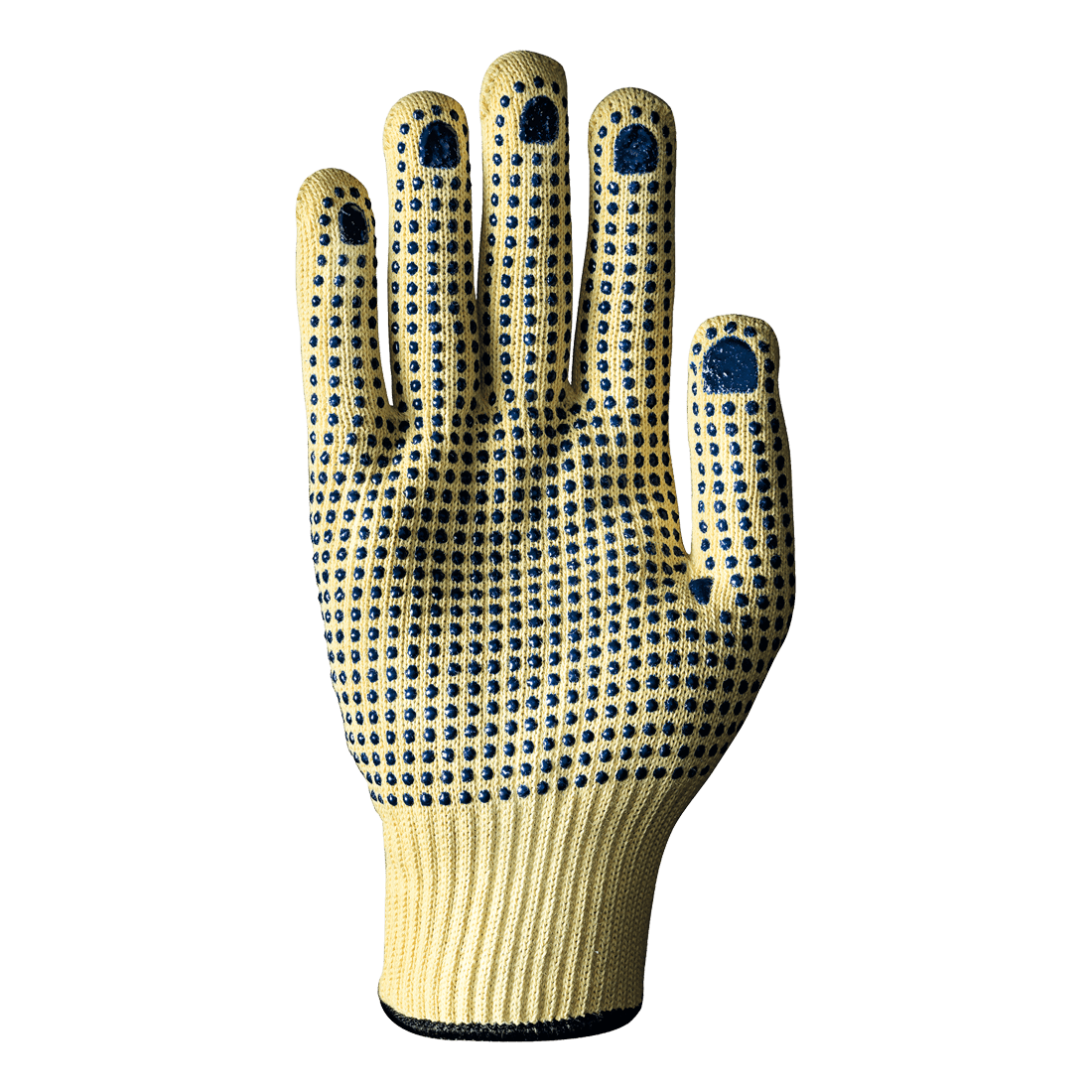

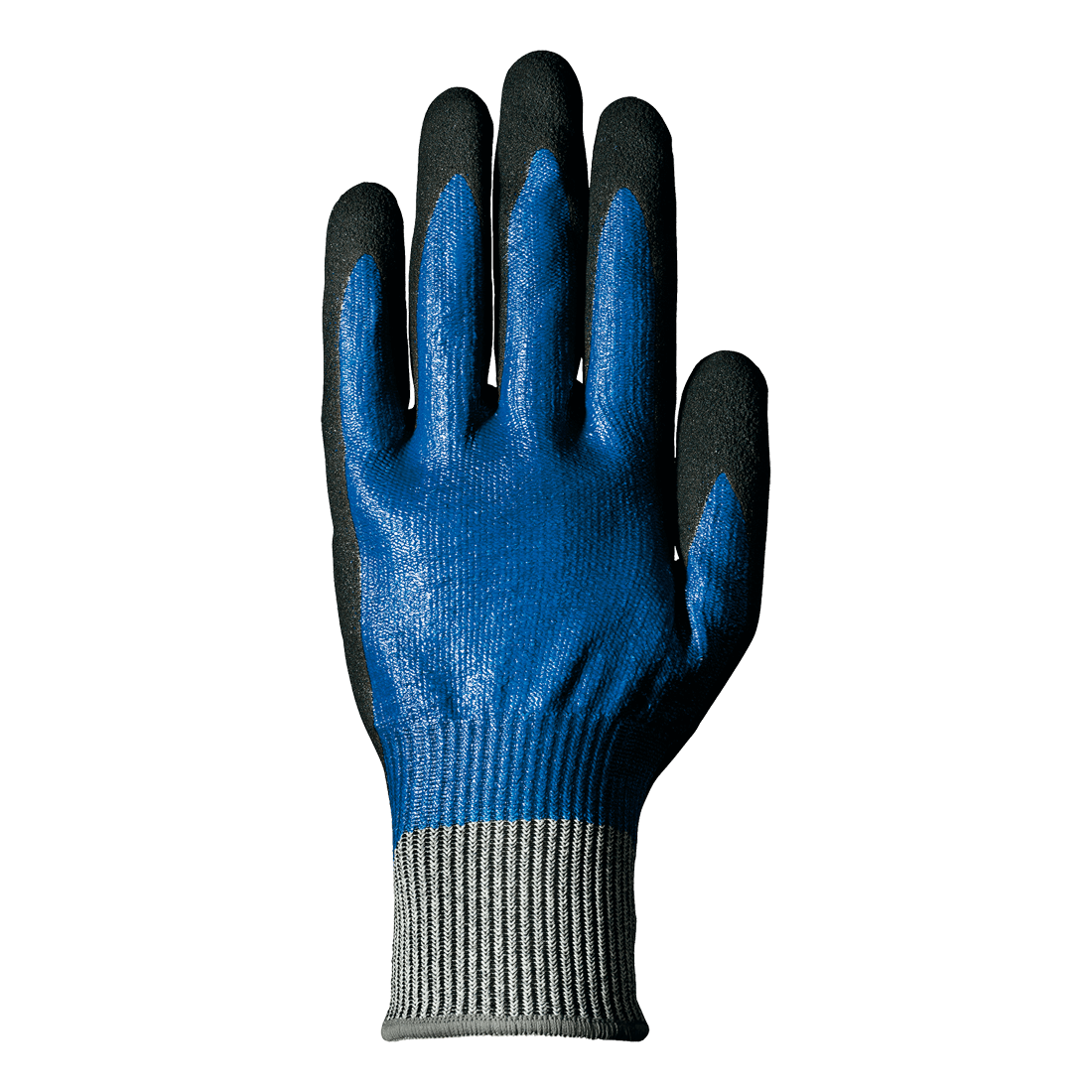

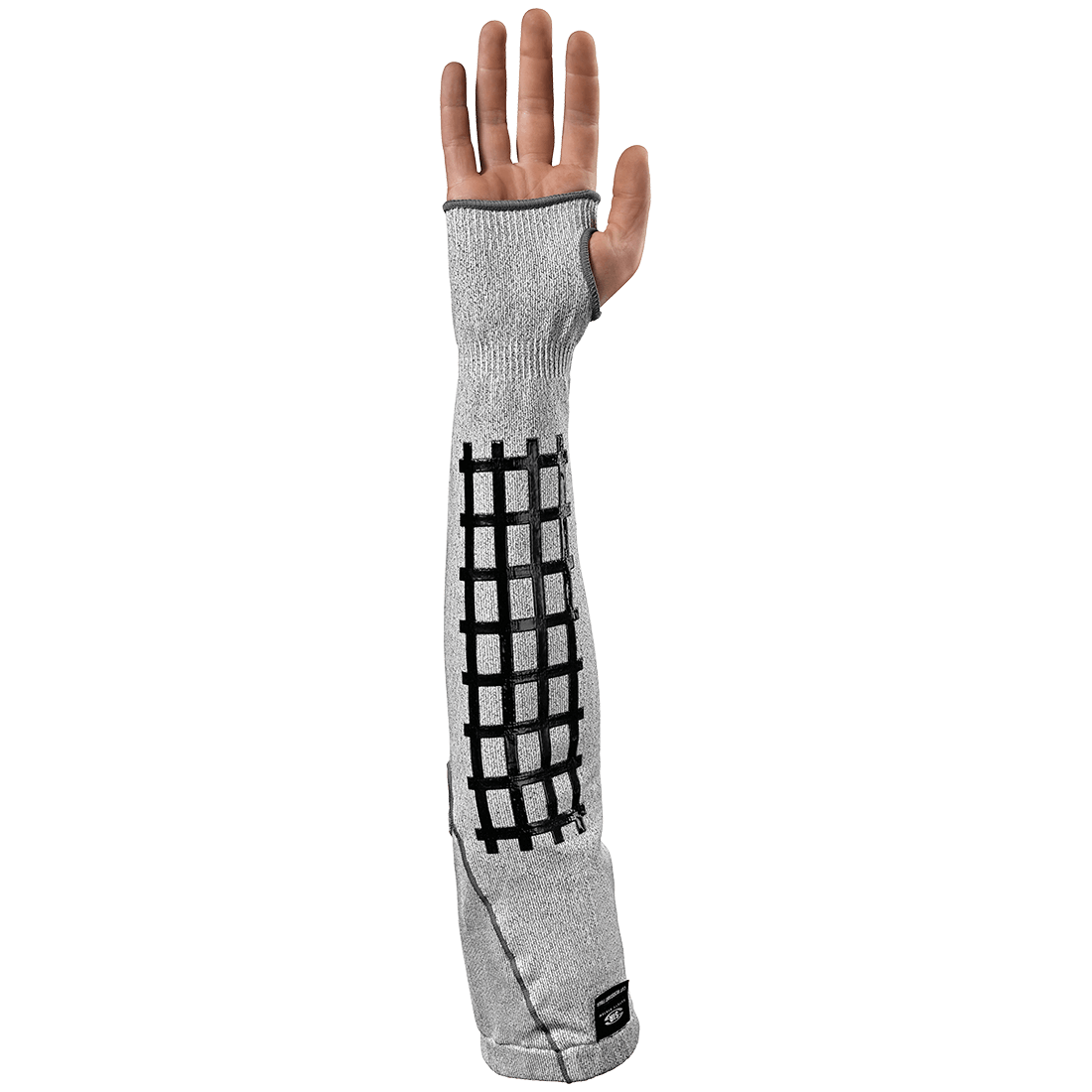

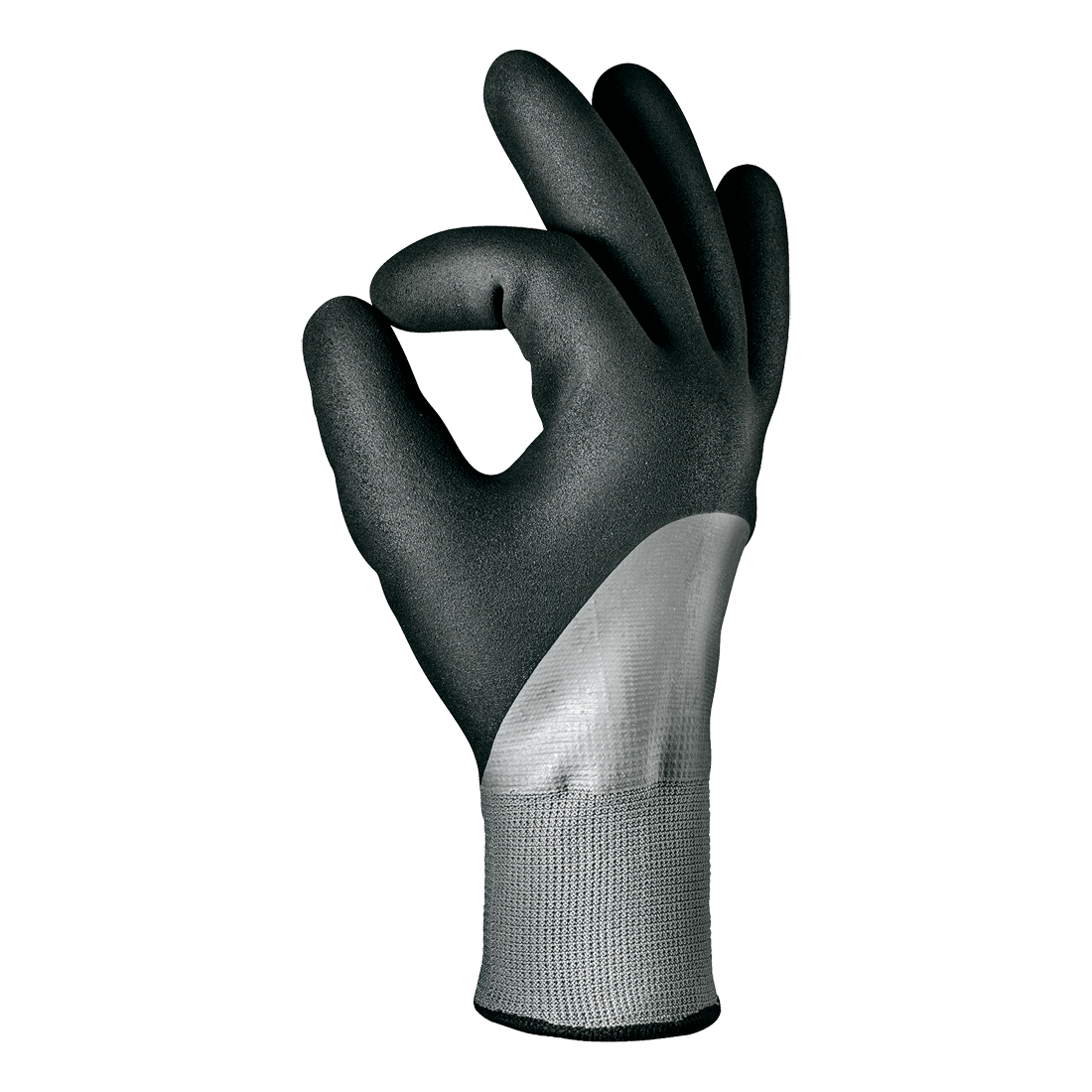

Products for this standard